How to make downlight shell waterproof

The guardrail tube of downlight shell is used for external interface, led silica gel seal, internal circuit exposed, large temperature difference between day and night, end cover and thermal expansion and contraction, resulting in silicone seal cracks. After rainwater enters the room, what results can be imagined. In order to solve this problem, for some requirements of internal circuit and downlight shell, the outside of silica gel sealing cover is simple, but the reliability is not high, so it is applied in large-scale outdoor.

Connection of electric connection of downlight shell. When I do the experiment, the signal wire has corrosive rust sample when it is electrified 8 hours after contacting with water. Poor metal joints only need a small part of the price of the regular manufacturers, due to the surface treatment and material itself, it is very simple rain corrosion, constitute a short circuit. Many manufacturers often choose cheap plastic or metal joints, poor quality, short testing and application time, no plastic deformation, water is no problem, but with the sun shining, the temperature difference between day and night after the season changes, plastic deformation will lead to the failure of the waterproof rubber ring, the short circuit of the rain water in the internal connecting wire, especially in the case of electrified, the steel wire corrosion is higher than the case of no electrified.

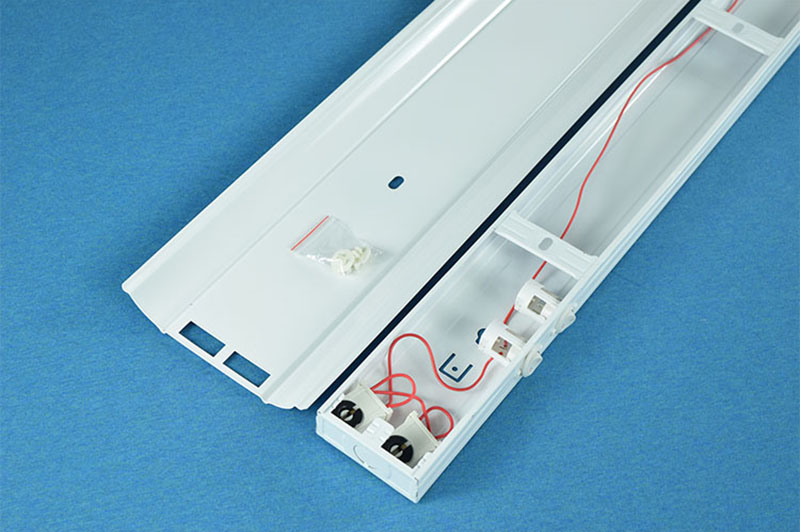

In the production of downlight shell, there are two kinds of shell, one is single type, the other is integrated type. So, are the key of the two types of shell the same?

1. Do not scratch or bump each line during the process of lighting equipment to prevent short circuit burning of the lamp, and do not short-circuit the power supply (positive and negative pole contact).

2. Pay attention to the equipment of each component, power controller and bracket, and tighten all screws.

3. Pay attention not to clamp the conductor at the connection of lamp pole when threading. The connection of conductor shall be firm and surrounded by PVC tape.

4. Do not use the parts not recommended by the manufacturer, otherwise it is likely to cause harm or risk to the system.

5. When purchasing the lamp holder, if the driving power supply of the lamp holder is wrong and hidden, it is recommended that the device be at the junction door of the lamp post (communicate with the manufacturer in advance).

6. In case of equipment cable, it is recommended to install fuse (fuse) at the junction door of light pole, and if necessary, it can be reduced and discarded.

7. If the lamp pole equipment is close to the transformer or the local voltage is unstable, it is recommended that the equipment voltage regulator can prevent the damage of the lamp head.

At that time, the cost and heat dissipation of LED lights were still a major technical difficulty, that is to say, no company could break through at that time, so your appearance at that time could not be prevented.

Energy saving lamp itself will announce most of the heat, you can touch the energy-saving lamp, hot. LED chip will also heat, heat dissipation depends on the lamp itself. So it is very important to heat the LED lamp. Compared with the energy-saving lamp, the energy-saving of LED lamp is not obvious.

Article source: downlight shell manufacturerhttp://www.jinleidj.com/

-

05-04

What is wrong with the purchase of downlight shell

With the increasingly strong sound of energy conservation and environmental protection, we are using more and more LED lights in lighting design. LED market is now a mixture of good and bad, manufacturers and businesses are pushing and blowing their own products. So what do you know about LED line lights?The selection of LED lamps includes appearance, heat dissipation, light distribution, glare, e

-

05-04

Common chips of downlight shell

We are not unfamiliar with downlight shell, which is one of the commonly used LED lamps in daily life. However, we often neglect the small chip when we choose and buy it, which leads to losses. Although the chip is small, it plays an important role in the downlight housing, because it touches the light efficiency and life of the downlight housing, so you must pay attention to it when you buy it. W

-

05-04

Precautions for the purchase of downlight shell accessories

Good quality is not what is blown out. If you want to choose high-quality lighting accessories, you need to pay attention to several key points:1. Look at the packaging and trademark. The state forces the manufacturer of downlight shell to mark the following contents on the outer package: rated voltage, voltage scale, rated power and rated frequency. Generally speaking, the trademark printing qual

-

05-04

What is the heat dissipation method of downlight shell

As for downlight shell manufacturers, because the use of LED street lights is very long, so, when purchasing LED street lights, many people will pay attention to the heat dissipation problem of downlight shell. Generally speaking, this problem is solved, and the quality of LED street lights will not be very poor.1. The three prevention plan is selected outside the lamp to deal with the heavy dust