-

What are the advantages of metal stamping

2020-05-05 732

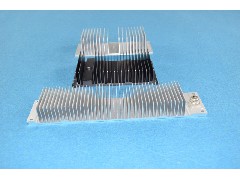

Compared with other methods of mechanical processing and plastic processing, stamping has many common advantages both in technology and economy. The main performance is as follows.(1) the stamping process has high production efficiency, convenient operation and easy completion mechanization and automation. This is because stamping depends on stamping die and stamping equipment to complete the proc

-

How to test metal stamping parts

2020-05-05 748

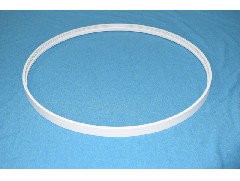

Rockwell hardness tester is selected for hardness test of hardware stamping parts. Small stamping parts with complex shape can be used to test the small plane, which can not be tested on ordinary Rockwell hardness tester.Stamping process includes blanking, zigzag, drawing, forming, finishing and other processes. The processing data of stamping parts are mainly hot-rolled or cold-rolled (mainly col

-

What is the influence on the quality of metal stamping parts

2020-05-05 716

Compared with other methods of mechanical processing and plastic processing, metal stamping has many common advantages both in technology and economy. The proportion of medium pressure mold in metal stamping parts processing industry will continue to improve. With the development of vehicle, motor and other products to the direction of lightweight, more and more requirements will be put forward fo

-

How to test metal stamping parts

2020-05-05 714

Rockwell hardness tester is selected for hardness test of hardware stamping parts. Small stamping parts with disordered shape can be used to test the small plane, which can not be tested on ordinary Rockwell hardness tester.Stamping processing includes blanking, zigzag, drawing, forming, finishing and other processes. The processing data of stamping parts are mainly hot-rolled or cold-rolled (main

-

What properties should metal stamping molding sand have

2020-05-05 728

The quality of molding sand and core sand has a direct impact on the quality of castings. Poor quality of molding sand will cause defects of castings such as porosity, sand hole, sand sticking and sand inclusion. Outstanding molding sand shall have the following functions:1) air permeability typeAfter the high temperature liquid metal is poured into the mold, the mold is filled with a large amount

-

How to check the quality of metal stamping parts

2020-05-05 720

1. Data viewingData quality control includes data acceptance check, data pre cleaning check, data post cleaning check and data pre production check. The intention is to recognize that the quality of data meets the production requirements.2. First article 1 sequence viewThe first piece of stamping determines the quality of the whole batch of parts, and the first piece 1 sequence inspection is an im

-

What are the processes of metal stamping parts

2020-05-05 712

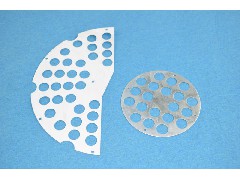

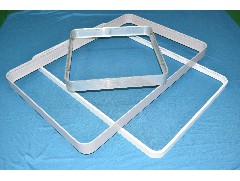

The primary and fundamental processes of stamping are blanking, punching, zigzag and drawing:(1) blanking and punching blanking and punching are processes to separate the blank. Blanking and punching process is exactly the same, just for different purposes. During blanking, the separated part is the finished product, and the remaining periphery is the waste material; punching is to obtain the hole

-

What are the processing technologies of metal stamping

2020-05-05 682

In stamping industry, stamping is sometimes called sheet forming, but there are some differences. The so-called sheet forming refers to the forming method of plastic processing with sheet, thin-walled tube, thin profile, etc. as raw materials. At this time, the deformation in the direction of thick plate is generally not considered.PHP series portable external Rockwell hardness tester is very suit